The calculation deals with the following tasks. Design of connections with butt welds. Design of connections with fillet welds. Design of connections with plug and slot welds. Design of connections with spot (resistance) welds. Strength control of designed connections. The slot weld symbol is the same that is used for plug welds. The symbol will not show a diameter symbol before the size however. The size of the weld will be the slot width instead. This is shown to the left of the symbol just as it is shown in plug welds.

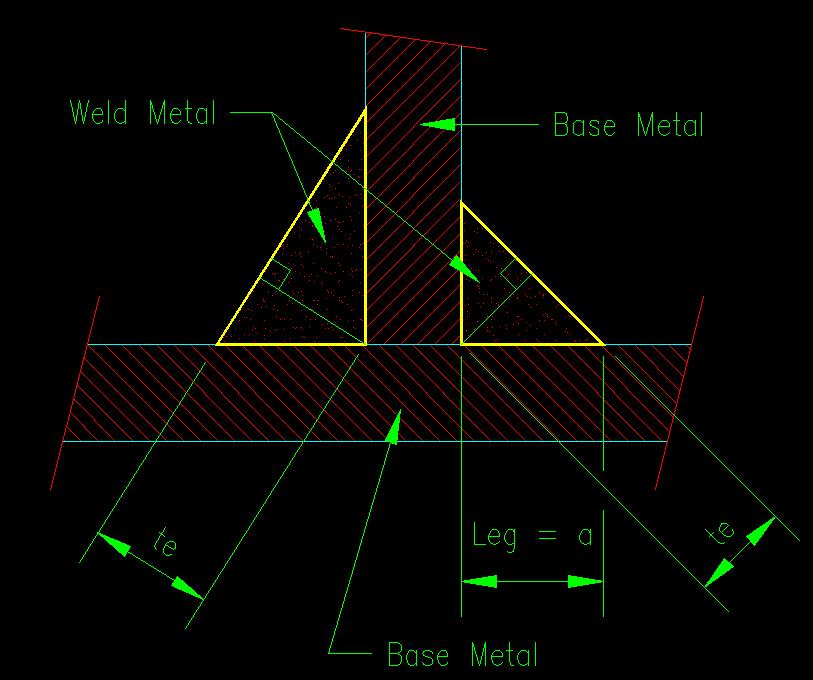

- Weld leg length (L) need to be find out using the eq.7 as: L=1.414.t = 1.414.0.331 = 0.468 mm. So, from the fillet weld size calculation example we found that the required minimum weld leg length to withstand the weld force is to be 0.468 mm, we will take the 3mm as the weld size for this example problem.

- Plug and Slot Welds. Straight Plug Welds. Bevelled Plug Welds. Straight Slot Weld. Bevelled Slot Weld. Side Fillet Bending. Side Fillet Point Load. Side Penetration Bending. Side Penetration Point. Side Penetration Torsion.

- One-shear joint loaded with shear Shear loading of a point Tear loading of a point along the cylindrical surface Comparative stress Meaning of used variables F acting force N, lb d diameter of spot weld mm, in i number of welds - s plate thickness mm, in α conversion factor of weld joint - Double-shear joint loaded with shear Shear loading of a point Tear loading of a point along.

WelderDestiny ›Welding Engineering Tools ›Calculating Welding Costs

Calculating welding costs and times are important because weldingcan be a significant part of the costs in fabricating welded structures andcomponents. Knowing how to estimate the volume of weld to be deposited, and thetypical time it will take to perform the welding is important to preparequotations and also to plan schedules.

The WelderDestiny Compass: Weekly e-zine Subscription

You can take a look at 'The WelderDestiny Compass' back-issues by clicking here.

Thereare many resources available that approach the issues associated with calculating welding costs from different perspectives,so it is important to note that there are a number of ways to get to an answer.The approach taken in this web page is a relatively fundamental approach thatshould be easily modified for use in most instances. The steps taken to calculating welding costs and times are as follows:

- Calculatethe volume of weld metal to be deposited. This is essentially based on the weldpreparation and the length of weld.

- Calculatethe mass of weld metal that needs to be deposited, based on the density of theparticular material that you are working with.

- Applya “recovery factor” to the weld mass calculated, to estimate the total amountof welding consumable needed. (Some of the consumable will be wasted and willnot end up in the joint. For instance, in the case of Shielded Metal ArcWelding (SMAW) there will be stub losses, slag losses and spatter losses.)

- Basedon the mass of welding consumable needed, you will now be able to find out thecost of the welding filler metals by getting an appropriate quote from yourfiller metal supplier. This does not account for “supplementary” consumablessuch as shielding gas or grinding discs etc. You will need to calculate thosecosts separately, based on the type of job it is that you will be doing.

- Calculatethe time it would take to deposit the necessary mass of weld metal, based on adeposition rate for the particular welding process that you will be using. Thisvalue assumes a 100% “arc on” time.

- Applyan “arc on factor” to take account of the fact that no welder ever welds 100%of the time. There will be times when s/he needs to remove a stub and replacewith another electrode, or perform some grinding or other cleaning between weldruns etc. Obviously this factor will be different for each welder, but you canstart with a typical industry accepted value, and refine this for yourparticular business or project. (Your business may be more or less efficientthan the industry average, or the particular job may be more difficult,resulting in a lower arc on percentage. This is often the case for maintenancetype work)

- Thiswill now tell you how many “man hours” it will take to complete the job.

- Basedon the man hours, you can then estimate the length of time it will take tocomplete the job, by deciding how many welders will be welding at the sametime.

- Basedon the man hour calculation, and the assumption you have made of the number ofwelders welding at the same time, you can estimate how many welders you need,and for how long. When calculating your manpower costs at this point, do notforget to add in an allowance for assistants, and also “unproductive time”associated with your company’s systems and processes. (Think safety meetings,morning meetings, quality circles, safety inspections or other administrativeprocesses.)

- Eachbusiness will also have some “overhead cost” allowance based on the total timethe job will take. This takes account of the cost of management, qualitycontrol personnel, equipment, indirect consumables etc. These overhead costswill be different for each company, and will also vary widely between differentindustries. Sometimes the estimator just uses a factor based on the costscalculated above (e.g. Multiply costs calculated by 1.5 to account foroverheads.) and sometimes it will be an “overhead rate” based on the number ofwelding man hours. (e.g. $50 per man hour overhead cost.)

Please keep in mind that this discussion on calculating welding costs is only looking at the welding operation. It does not take accountof costs associated with materials or boiler making / construction activities.

Estimating Packages For Calculating Welding Costs

Slot Weld Calculations

Calculating welding costs and times would obviously be rather time consuming if we have to re-calculate the basics for everyestimate you need to do, so most businesses will have some kind of automatedestimating system. There are a number of generalized commercial estimatingpackages available, that can be used for almost any type of work. Theshortcoming of most of these generalized estimating systems is that themethodology for calculating welding costs and times are not not included in enough detail. In this situation, calculating welding times and costs are typically included in more specialized estimatingapplications that focus on the welding operation.

Manybusinesses therefore have a combination of commercial estimating packages,combined with a selection of spreadsheets to provide some inputs to thecommercial estimating package. Obviously, some businesses just use a selectionof spreadsheets to do their estimates, which would include calculating welding costs and times. This is especially the case for smallerbusinesses.

Help With Calculating Welding Costs and Times

Tohelp you with the calculating welding costs and times, we have made available a spreadsheetthat does the welding volume and time based calculations. You can download the spreadsheet by clicking here. While I have been careful to make a spreadsheet that makes reasonably accurate calculations, WelderDestiny does not take any responsibility for the answers you get from this spreadsheet. Please use at own risk.

Tohelp get you on your way, below are some explanations on how to use thespreadsheet for calculating welding costs and times. The spreadsheet contains two worksheets.The first worksheet deals with bevel, butt and fillet welds. The second dealswith TYK joints. The TYK joints are addressed separately because they are a lotmore complicated to calculate the weld volume.

Guidelines for calculating welding costs and times for the “Bevel Butt Fillet”worksheet:

- Inthe “Bevel Butt Fillet” worksheet, the weld details are captured on the topleft hand side.

- Inthe first column there are 5 different types of weld preparations described.(Each weld preparation has been replicated 4 times, to allow you to enter morethan one of each type if needed.) This is highlighted in yellow.

- Thenext 5 columns deal with the different dimensions associated with the differentweld preparations. This is where you enter the raw dimensional data for thecalculations. These columns have been highlighted in light blue. To exclude anyrow from the calculations, ensure that the value in the “Length” column iszero. (Currently, typical values have been entered, just to offer someguidance.) Please take note of the units used for the different dimensions.This worksheet has been completed in SI units. If there is enough demand, Iwill reproduce this in Imperial units, although it would be quite easy for youto make those modifications yourself.

- Thenext 4 columns are the outputs of the calculations. (Please note that if youchange anything in these columns, then the calculations will be affected, so becareful.) The calculations here take into account the dimensional data, alongwith the filler metal and welding details further down on the left hand side ofthe worksheet. These columns have been highlighted in light green.

- Sketchesshowing the different weld preparations and the associated dimensions are alsoincluded just to the right and below the calculation table.

- Thefiller metal details are entered in the light blue highlighted cells on theleft hand side below the calculation table.

- Thewelding details are entered in the light blue highlighted cells below thefiller details.

- Belowthe welding details is a list of terms used in the worksheet.

- Tothe bottom right of the worksheet, in line with the filler details are sometypical values that can be used for different welding processes and materials.Just above this are a couple of “quick calculators” for converting pounds perhour to kilogram per hour and inches to millimeters.

- Tothe bottom of the worksheet there are a lot of reference materials to help makedecisions regarding deposition rates and efficiencies. Please take care of theunits, as some of the references are in Imperial units and some in SI units.You can use the “quick calculators” to make any unit conversions required,before entering the values into the worksheet.

- Theresults from the worksheet calculations are summarized in the “Total” row thathas been displayed in a bold red font. The total filler requirement, includingthe allowance for weld metal recovery percentage is given in the “Total FillerRequired” cell.

Plug Weld Design Calculation

Pleasenote that the dimensional details entered in the worksheet will be subjected tovalues entered in the filler details and the welding details to obtain thenecessary calculations. This means that you can only deal with a single fillermetal and a single welding process at a time. This does complicate calculating welding costs and times for multi process welds, but it can stillbe done as follows:

- Firstapply the dimensional and welding data as though you were only welding the rootprocess. For example, if the root process was going to be a 1000mm long, 4mmthick Gas Tungsten Arc Welding (GTAW) deposit on a 20mm thick plate using a 60°included angle single Vee weld with a 4mm root gap, then you will enter: a =30; b = 2; T = 4; h = 0; Length = 1. (Make sure that you enter the necessaryGTAW values in the filler details and welding details sections.)

- Next,apply the dimensional and welding details as though you were only welding thefiller and cap process. If we are going to weld the rest of the joint describedin the point above with the Flux Cored Arc Welding (FCAW) process, then we willenter the following information for the FCAW section: a = 30; b = 5; (This isan approximation of what the “root gap” would be if we removed the GTAWsection.) T = 16; (20mm plate thickness minus the 4mm for the root process.) h= 3mm; (An approximation of how high the cap reinforcement will be.) Length = 1(Make sure that you enter the necessary FCAW values in the filler details andwelding details sections.)

- Thefiller metal and man hour values calculated from the two points above can thenbe used appropriately to perform the rest of the cost and time estimatecalculations.

Theguidelines for calculating welding costs and times for the “TYK Joints” worksheet are as follows:

- Thisworksheet is geared to “T” and “Y” joints between two pipe sectionsintersecting in a single plane. Out of plane pipe intersections, and “K” jointsthat intersect at the node would require some modifications to get accurateanswers, although the answers will not be too far off.

- Onthe top left hand side of the worksheet, we have the main dimensional information.This is largely based on the diameter of the smaller member, and the angle thatthe smaller member makes with the main member.

- Thelight blue cells are where you need to enter the necessary information.

- Thelight green cells show you calculated information. As a general rule you do notwant to mess around with the green cells.

- Belowthe dimensional information on the top left hand side is where the fillerinformation is entered. (In the light blue cells.)

- Forthe TYK Joints worksheet you need to enter the information for the root and the“main” welding processes. This allows you to do the entire calculation in onego, when you have different processes for the root and filler / cap. If youonly have one process, then enter a root thickness of 0mm.

- Belowthe filler and welding process details sections on the worksheet, is the “TYKJoint Weld Detail Information” input section. This is a matrix that furtherdefines the weld preparation details for the different parts of the weld.

- Onlyenter the relevant dimensional information in the cells that have beenhighlighted in light blue. The cells highlighted in light green are calculatedvalues, so do not mess with those cells.

- Toassist in choosing which of the different weld details are appropriate, there arefour sketches included on the right hand side of the worksheet. (Detail 36;Detail 37; Detail 38; Detail 39)

- Youneed to select one “Toe of Weld” row, one “Sides of Weld” row and one “Heel ofWeld” row to use in the calculations. You select this by placing a 1 (Yes) or 0(No) in the relevant cell of column “G” of the weld detail matrix. Be guided bythe descriptions in column A and the angles given in column B. (Note that thisis based on the details given in AWS D1.1, but you need to select the most appropriateweld details.

- Pleasedisregard the grey highlighted block on the bottom right hand side of theworksheet. This is used for embedded calculations. If you mess with thesecells, you will get wrong answers.

- Thecalculated filler metal quantities and man hours are specified below the welddetail information, and is highlighted in pink.

- Pleaseread the “Notes” section on the bottom left hand side of the worksheet forfurther guidance on the use of the worksheet.

Byusing the worksheets supplied, you should be able to get the necessary weldingconsumable and welding man hour values required to perform the higher levelcosting estimates for your welding job.

WelderDestiny ›Welding Engineering Tools ›Calculating Welding Costs

The WelderDestiny Compass: Weekly e-zine Subscription

Weld Time Calculator

You can take a look at 'The WelderDestiny Compass' back-issues by clicking here.