Craftsman Extreme Grip Long Reach Slotted Screwdriver 1/4X 8IN. Vise Grip Irwin Vise-Grip Stanley® Products 25ZR IRWIN VISE-GRIP Locking Welding Clamps, 2-3/4 in Jaw Opening, 9 in Long 25ZR Pack of 1 (4) Sold by SIM Supply. Add to compare compare now. Vise Grip Irwin Vise-Grip Stanley® Products 21 IRWIN VISE-GRIP The.

KURT 5-AXIS WORKHOLDING

Introducing new Precision Force MaxLock™ vises. Available now for preorder and August delivery.

- 1.94' OAL, 16mm T slot, 17,800 N Holding Force, Steel, T Slot Toe Clamp 0.62' Body Height, 0.38' Jaw Height, 1' Overall Height, 1.12' Wide MSC# 80447493 Mitee-Bite (54018) Ships from Mfr.

- IRWIN VISE-GRIP C Clamp, Locking with Swivel Pads, 4-inch (165) 4.5 out of 5 stars 168. Get it as soon as Tue, Dec 8. FREE Shipping on orders over $25 shipped by Amazon. Other options New from $9.90. Vise Grip VGP24SP Plain Handle Alloy Steel Locking C-Clamp.

- Product Title OTVIAP Woodworking Tool,T-Slot Clamp,Metal Quick Acting Hold Down Clamp Set for T-Slot T-Track Woodworking Tool Average Rating: ( 0.0 ) out of 5 stars Current Price $8.73 $ 8. 73 List List Price $13.97 $ 13.

KURT WORKHOLDING SOLUTIONS

Holding your products — and our competitors’ attention — since 1959.

KURT AUTOMATION SOLUTIONS

Excellence is automatic. Our automated processes increase speed, accuracy, and employee satisfaction.

KURT CUSTOM WORKHOLDING SOLUTIONS

Our custom vises are designed to work for you — and only you.

KURT GAGING SOLUTIONS

Precision is everything. Kurt gaging solutions keep you focused on delivering perfection.

KURT TOWERS

Kurt vises and towers grip so tight, they even hold our competitors’ attention.

PRECISION BY DESIGN.

PERFECT BY DESIRE.

When you demand quality, Kurt delivers every time. Kurt vises sets the standard in reliability for CNC machining or precision workholding requirements. No other company comes close to the variety, dependability, or precision of Kurt vises. And it shows.

The original Kurt AngLock® vises were designed to provide precision part clamping for basic machining and milling applications. Our line of Kurt vises includes high precision CNC vises, 5-axis vises, rotary table workholding solutions for VMCs, and ToolBlox tombstones. Our precision workholding solutions provide increased versatility at your CNC machining stations. Precision measuring systems and accessories are also available to complement your Kurt workholding system.

By Doug Ripka

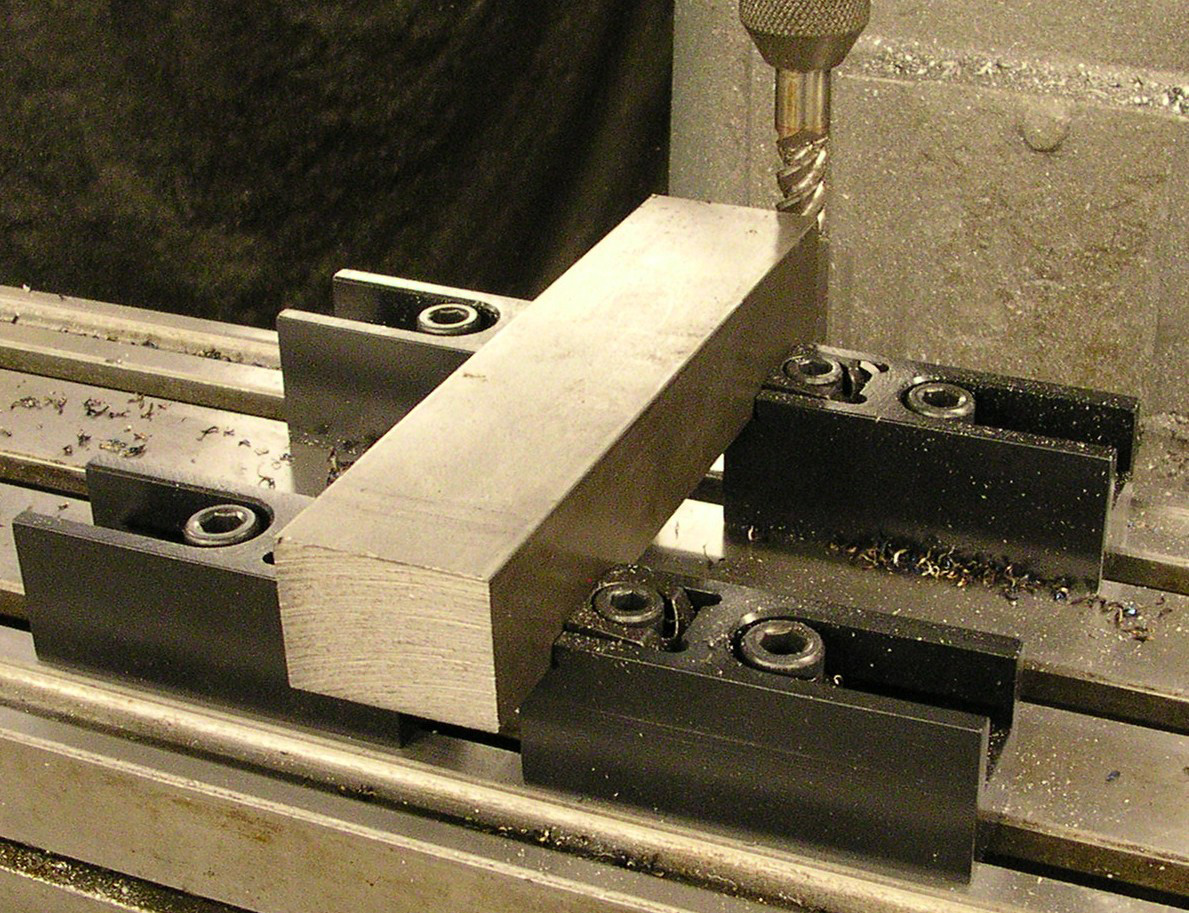

We recently bought a small Jet drill press at work. The drill has T-slots in it instead of the open slots our old drill press had, so we couldn’t use our Vise-Grip style table clamps that we had grown fond of. (One example of what we are using is the Grizzly H1127 drill press table clamp. It has the toggle action of a Vise-Grip combined with a threaded stud.)

Vise Grip Bar Clamps

To remedy this, I drilled some holes in the bottom of the T-slots to accommodate the threaded stud of the clamp (Photo 1). I drilled one 1/2” hole 5” from center for our larger clamp and two 3/8” holes at 3” and 4” from center for our smaller clamps (Photo 2). I also put each of the three holes in different T-slots so as not to weaken one slot excessively, as the cast iron did not look very thick to me. As the table spins 360 degrees, any hole can be put in any orientation relative to the center for the best clamping option. I was also able to drill the holes using the drill press, so you can accomplish this with only the tool itself.

C Clamp Vise Grips

Thanks Doug. Your subscription has been extended by an issue!

Vise Grip Chain Clamp

Please do us a tremendous favor and share this tip with your machining friends!